Cutting Underwater Technologies Ltd

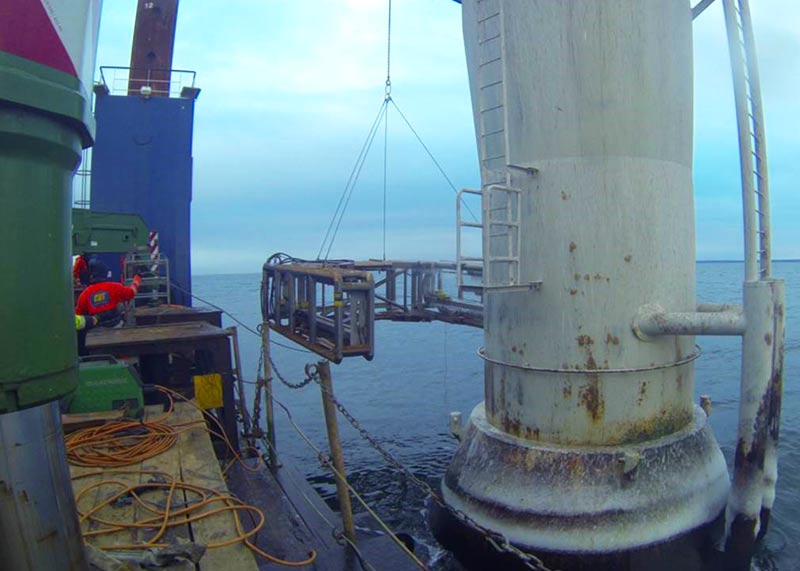

Cutting Underwater Technologies Limited (CUT), a wholly owned subsidiary of TS Tecnospamec S.r.l, is a leading subcontractor for the provision of diamond wire cutting services. CUT provide off the shelf and bespoke engineered diamond wire cutting solutions for clients operating in the Oil and Gas, Nuclear, Renewable and Decommissioning sectors. CUT’s aim is to be the industry leader in the provision of diamond wire cutting solutions globally.

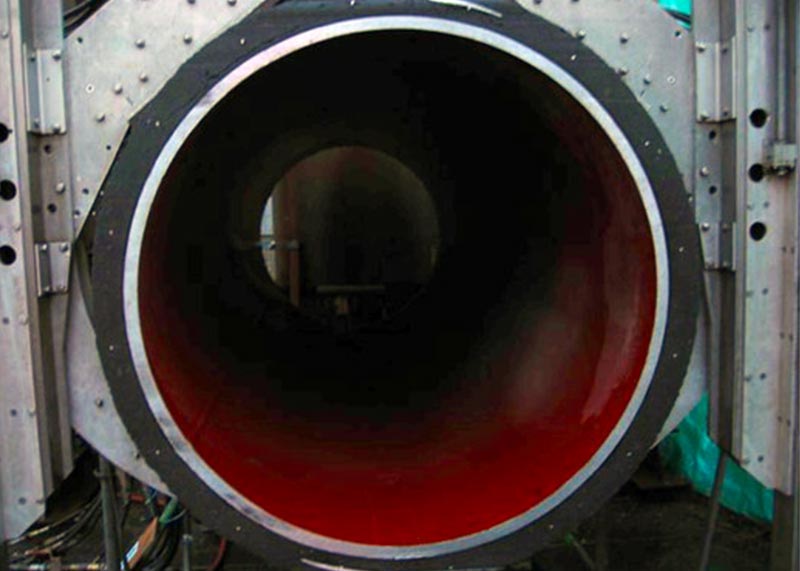

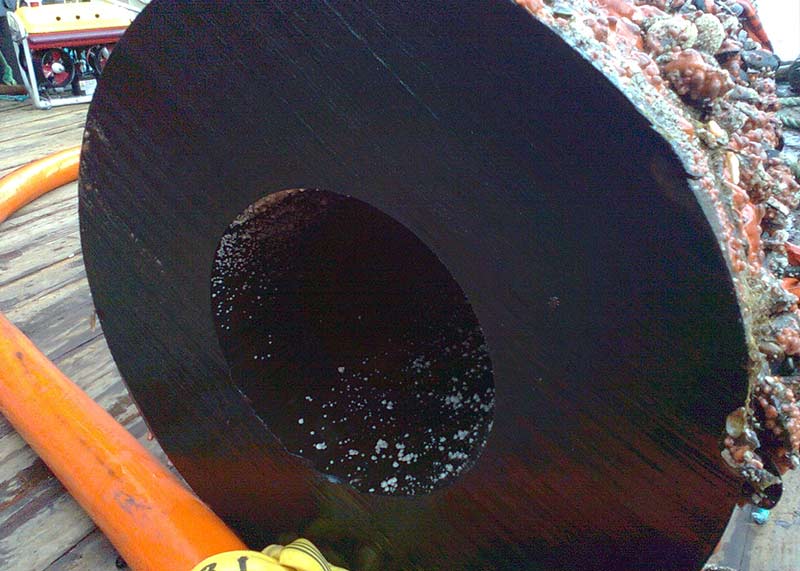

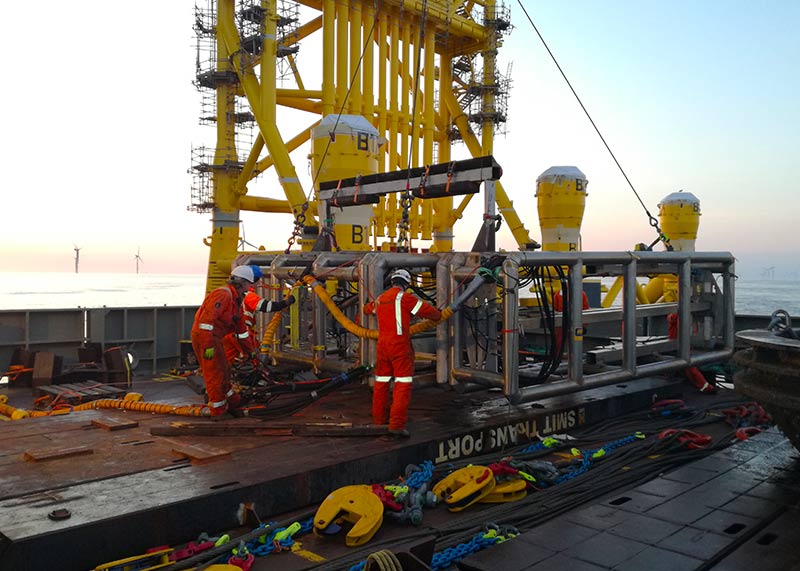

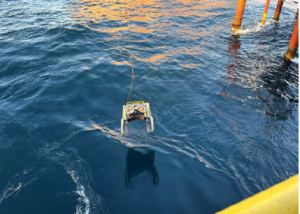

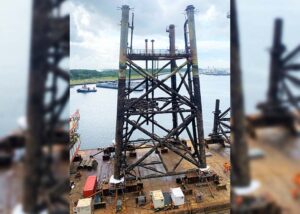

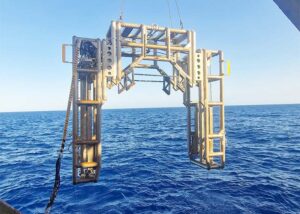

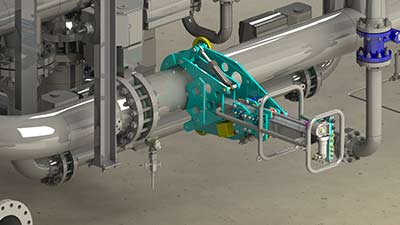

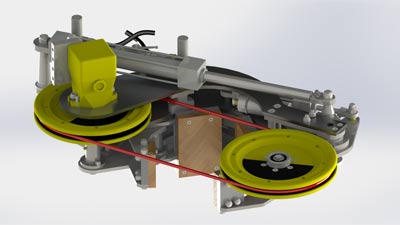

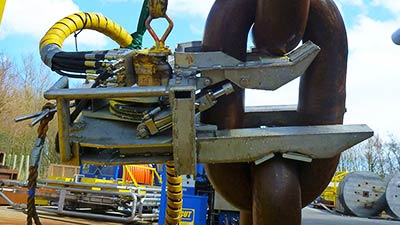

Diamond Wire cutting Machines or Diamond Wire Saws can be used to cut virtually any structure including anchor chain / mooring chain, jacket removal, platform removal, decommissioning, pile cutting, piles with grout and internal pipework, launch runner c/w launch runner wood, concrete structures. The versatility for Diamond Wire cutting is endless. With over 8000 successful cuts to date, check out our Track Record for a full list.

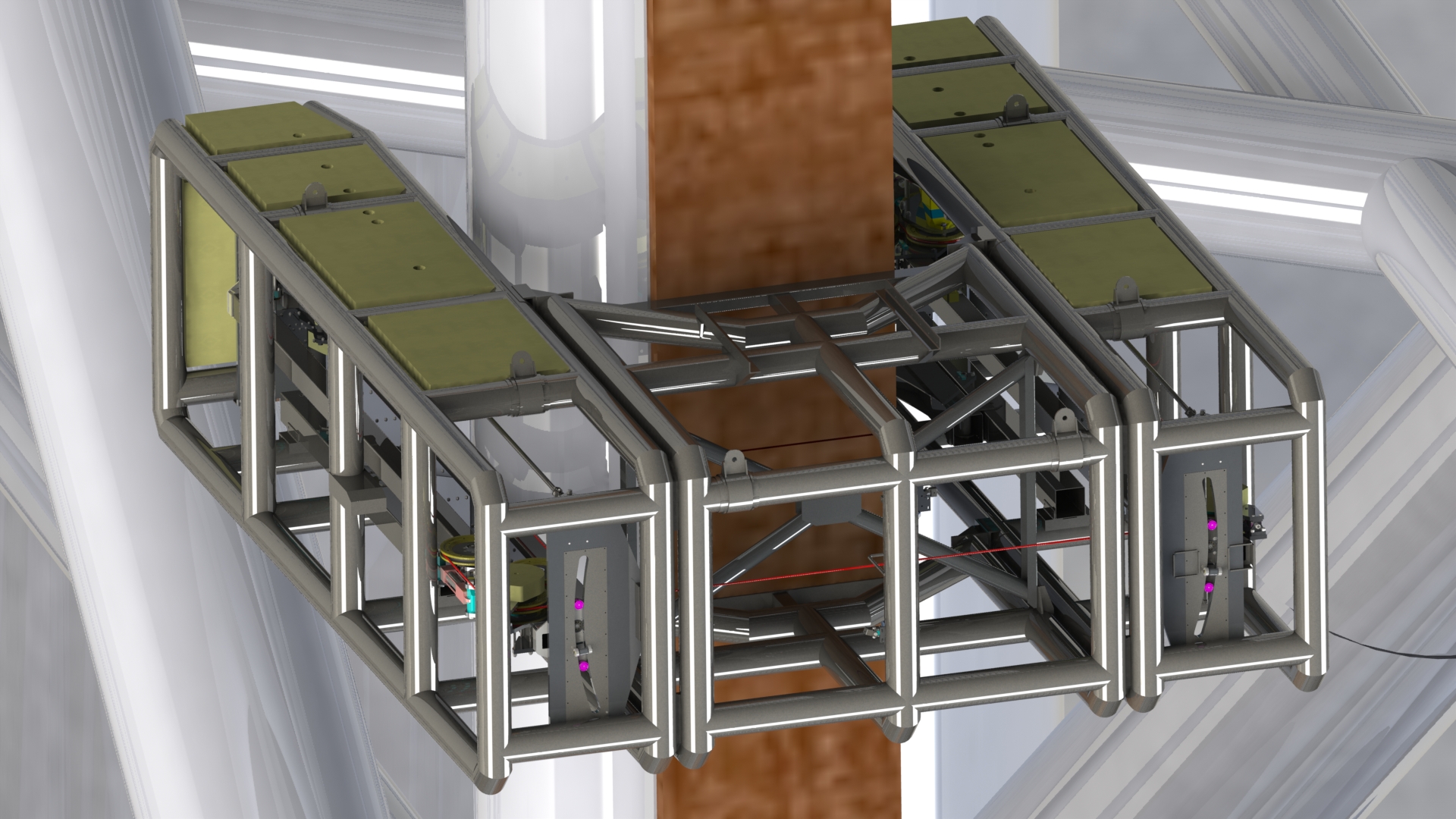

The CUT fleet offers a range of almost 150 Diamond Wire Cutting Machines / Saws. CUT offers full Project Management for cutting projects as well as development of bespoke and project specific Diamond Wire Cutting Machines (DWCM), worldwide. The Diamond Wire Cutting technology was invented and developed in house which uniquely positions CUT as a leader and innovator.

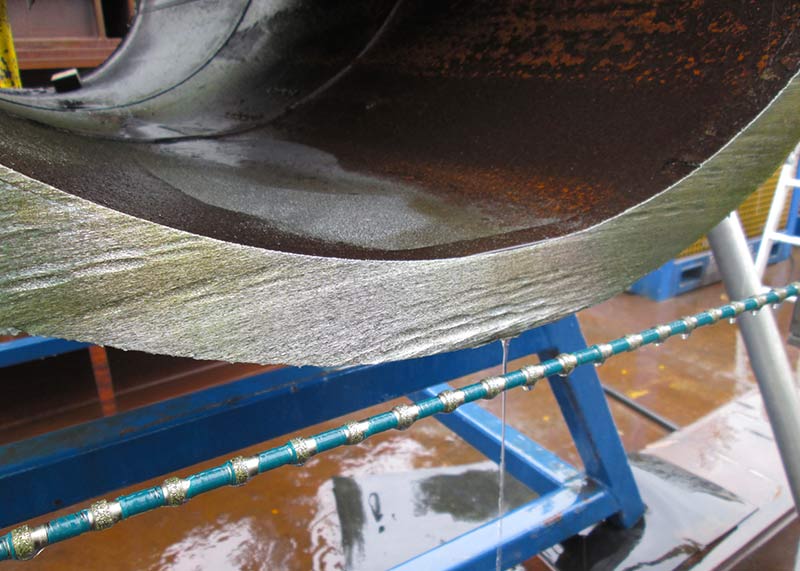

One such innovation is castellated and step cuts which were specifically engineered solutions requested by the decommissioning industry to help maintain integrity of the jacket following completion of the cut.

The patented operation of castellated / step cuts help to maintain the stability of a jacket / platform during cutting and removal operations, effectively locking the jacket or platform in position after the cutting operation. This gives increased operational safety and allows the jacket / platform to be left in-situ until lifting operations can be scheduled.

CUT provide responsive and creative diamond wire cutting solutions both on and offshore, with a well-established track record in Europe, Middle East, Africa, USA and Norway. CUT have demonstrated our professional expertise by researching, developing and operating our technologies and systems globally for more than thirty five years, building a reputation for working safely, in a timely manner and within budget.

years of experience

Industry leader & innovator for Diamond Wire Cutting

completed projects

for platform and pipeline removals, pipeline repairs, multi-strings, chains, flexibles and more..

completed cuts

across all industry sectors. For a more detail look at our track record page.